Difference between revisions of "Ion Source"

| (13 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | + | ==Background== | |

| − | + | The ion source we will be using is a General Ionex 860A Inverted Sputter negative ion source. We use negative ions so that we can benefit from (ie. accelerate with) the voltage of the [[Tandem]] Van de Graaff twice. Sources of this type have been commercially available for about 25 years and are still sold by National Electrostatics Corporation (the [http://www.pelletron.com/negion.htm SNICS]), High Voltage Engineering Europa (the [http://www.highvolteng.com/ionsources.html 860A and C] and Peabody Scientific (the [http://www.peabody-scientific.com/page3.html PS-120]. | |

| − | + | ==Theory of Operation== | |

| + | An inverted sputter source works by creating a beam of positive ions which hit a sample of the material of interest. The positive ions deposit several atomic layers deep and stimulate the sample to sputter out material. Any negative ions which are released are extracted by a large negative potential. | ||

| + | |||

| + | The positive beam in an 860A source consists of cesium plus one (Cs<sup>+</sup>) ions. The source of Cs is called the boiler; it is a small vacuum which holds about 1 gram of Cs with a 40 Watt heater. The Cs boiler temperature is controlled through the current on the boiler power supply. | ||

| + | |||

| + | Cs vapor enters the source head through a feed tube. The neutral Cs vapor finds the ionizer, a coil of tantalum co-axial wire which is heated to 1200<sup>o</sup>C. Cesium vapor pressure is very high at 1200<sup>o</sup>C so the Cs immediately evaporates. However, Ta has [http://environmentalchemistry.com/yogi/periodic/Ta.html work function] of 4.25 eV while Cs has an [http://environmentalchemistry.com/yogi/periodic/Cs.html ionization potential] of 3.89 eV. Therefore, it is energetically favorable for the Cs to evaporate as Cs<sup>+</sup>. | ||

| + | |||

| + | These Cs<sup>+</sup> ions experience an acceleration toward the sample holder of 3-5kV created by the cathode power supply. | ||

| + | The sputtered negative ions are ''pulled'' out by the extraction power supply, typically at 15kV. | ||

| + | |||

| + | More information on the inverted sputter source can be found from manufacturers such as [http://www.pelletron.com/negion.htm NEC] | ||

| + | |||

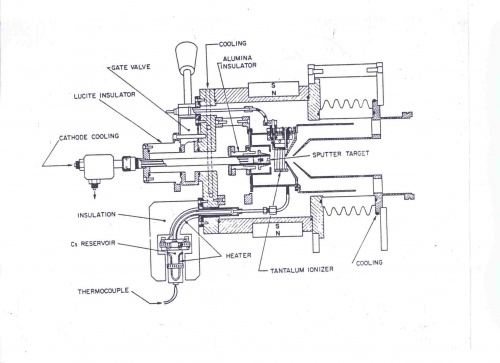

| + | [[Image:IonSource-1.jpg|500px|thumb|left| Schematic of the 860A]] | ||

| + | [[Image:IonSource-2.jpg|thumb|500px|right| Photo of the 860A, from HVEE]] | ||

| + | |||

| + | <br> | ||

| + | ==Operation== | ||

| + | |||

| + | ===Preparation=== | ||

| + | |||

| + | Before one operates the ion source, there are checks to perform. Only then can one switch the AC power for the ion source table from "wall power" to the motor-generator set. Typically students will do these steps under the direct supervision of the accelerator staff. | ||

| + | |||

| + | It is wise to check that the LabView control system is running before taking further steps. Use the Measurement and Automation Explorer (MAX) to see that all of the satellite computers are on and responding. If a machine does not respond, try a soft re-boot using MAX. If this fails, it may be necessary to do a hard re-boot at the machine. | ||

| + | |||

| + | * Checks: DI water, Vacuum, Gates | ||

| + | * Isolating vacuum and preparing Turbo to be off | ||

| + | * Switching AC Power source | ||

| + | * Restoring vacuum | ||

| + | * Turning on power supplies at Table, Magnet and Source stations | ||

| + | * Closing the Cage | ||

| + | * Opening LE Tube Valve | ||

| + | * Turning on AC power for the Cathode, Extraction and Glassman (table/injection/pre-accel) power supplies | ||

| + | |||

| + | ===Start-up=== | ||

| + | |||

| + | * Ensure that the ion source drive shaft is on, vacuum is good, power supplies are on, gate is closed, LE Tube valve is open | ||

| + | * Ensure that the control system is running. On MasterRT.vi front panel do the rest. | ||

| + | * Ensure that the LE Faraday Cup is in (Green, as of 8/21/2010) and that the selector switch sends that current to the electrometer | ||

| + | * Ensure that the Extraction Voltage is ~15 kV, the Inflection Magnet is near a useful ion mass (1, 12 or 16 are good choices). | ||

| + | * Raise the ionizer voltage to 8V gradually over a few minutes. Do not exceed 22 Amps. You will observe the heating of the Tantalum by an increase in the resistance of the ionizer. OK, at the very end you may exceed 22 amps if required to reach 8V. | ||

| + | * Set other parameters to likely values: | ||

| + | ** Einzel Lens to 3 kV | ||

| + | ** Variable Steerer to same as Fixed Steerer | ||

| + | ** Ground Station Triplet X to 1.1KV and Y to 1.2KV | ||

| + | ** LE Steerer H to -700V and V to +1100 V (note, these units are bogus as of 8/2010) | ||

| + | * Once the ionizer has 8V (~175 Watts) raise the Cathode Voltage slowly. If you see rapid changes to the Extraction Voltage/current or cathode current or a decrease in the ionizer current there may be sparking. In this case, lower the cathode voltage below the sparking point and wait. Increase slowly. A good first value will be 2 kV. | ||

| + | |||

| + | ===Tuning=== | ||

| + | |||

| + | * Observe the LE Faraday Cup [[Faraday Cups | LE Faraday cup]] current on the electrometer. Note that it should be negative. Recently we have found that one must wait 15 minutes for current to appear: Don't Panic. Once current appears you can tune all of the above mentioned parameters (not the ionizer, however!). | ||

| + | ** If there is no current, note your starting value and scan the Inflection magnet. Hint: mass 16 will be present for any sample unless there is something wrong with the set-up. | ||

| + | |||

| + | ===Troubleshooting=== | ||

| + | |||

| + | If the beam cannot be found or has a low beam current: | ||

| + | *The cesium boiler can be "pushed"; a higher Cs boiler temperature results in higher Cs vapor pressure and higher Cs current. | ||

| + | |||

Return to [[Lab Manuals]] | Return to [[Lab Manuals]] | ||

Latest revision as of 11:13, 5 October 2010

Contents

Background

The ion source we will be using is a General Ionex 860A Inverted Sputter negative ion source. We use negative ions so that we can benefit from (ie. accelerate with) the voltage of the Tandem Van de Graaff twice. Sources of this type have been commercially available for about 25 years and are still sold by National Electrostatics Corporation (the SNICS), High Voltage Engineering Europa (the 860A and C and Peabody Scientific (the PS-120.

Theory of Operation

An inverted sputter source works by creating a beam of positive ions which hit a sample of the material of interest. The positive ions deposit several atomic layers deep and stimulate the sample to sputter out material. Any negative ions which are released are extracted by a large negative potential.

The positive beam in an 860A source consists of cesium plus one (Cs+) ions. The source of Cs is called the boiler; it is a small vacuum which holds about 1 gram of Cs with a 40 Watt heater. The Cs boiler temperature is controlled through the current on the boiler power supply.

Cs vapor enters the source head through a feed tube. The neutral Cs vapor finds the ionizer, a coil of tantalum co-axial wire which is heated to 1200oC. Cesium vapor pressure is very high at 1200oC so the Cs immediately evaporates. However, Ta has work function of 4.25 eV while Cs has an ionization potential of 3.89 eV. Therefore, it is energetically favorable for the Cs to evaporate as Cs+.

These Cs+ ions experience an acceleration toward the sample holder of 3-5kV created by the cathode power supply. The sputtered negative ions are pulled out by the extraction power supply, typically at 15kV.

More information on the inverted sputter source can be found from manufacturers such as NEC

Operation

Preparation

Before one operates the ion source, there are checks to perform. Only then can one switch the AC power for the ion source table from "wall power" to the motor-generator set. Typically students will do these steps under the direct supervision of the accelerator staff.

It is wise to check that the LabView control system is running before taking further steps. Use the Measurement and Automation Explorer (MAX) to see that all of the satellite computers are on and responding. If a machine does not respond, try a soft re-boot using MAX. If this fails, it may be necessary to do a hard re-boot at the machine.

- Checks: DI water, Vacuum, Gates

- Isolating vacuum and preparing Turbo to be off

- Switching AC Power source

- Restoring vacuum

- Turning on power supplies at Table, Magnet and Source stations

- Closing the Cage

- Opening LE Tube Valve

- Turning on AC power for the Cathode, Extraction and Glassman (table/injection/pre-accel) power supplies

Start-up

- Ensure that the ion source drive shaft is on, vacuum is good, power supplies are on, gate is closed, LE Tube valve is open

- Ensure that the control system is running. On MasterRT.vi front panel do the rest.

- Ensure that the LE Faraday Cup is in (Green, as of 8/21/2010) and that the selector switch sends that current to the electrometer

- Ensure that the Extraction Voltage is ~15 kV, the Inflection Magnet is near a useful ion mass (1, 12 or 16 are good choices).

- Raise the ionizer voltage to 8V gradually over a few minutes. Do not exceed 22 Amps. You will observe the heating of the Tantalum by an increase in the resistance of the ionizer. OK, at the very end you may exceed 22 amps if required to reach 8V.

- Set other parameters to likely values:

- Einzel Lens to 3 kV

- Variable Steerer to same as Fixed Steerer

- Ground Station Triplet X to 1.1KV and Y to 1.2KV

- LE Steerer H to -700V and V to +1100 V (note, these units are bogus as of 8/2010)

- Once the ionizer has 8V (~175 Watts) raise the Cathode Voltage slowly. If you see rapid changes to the Extraction Voltage/current or cathode current or a decrease in the ionizer current there may be sparking. In this case, lower the cathode voltage below the sparking point and wait. Increase slowly. A good first value will be 2 kV.

Tuning

- Observe the LE Faraday Cup LE Faraday cup current on the electrometer. Note that it should be negative. Recently we have found that one must wait 15 minutes for current to appear: Don't Panic. Once current appears you can tune all of the above mentioned parameters (not the ionizer, however!).

- If there is no current, note your starting value and scan the Inflection magnet. Hint: mass 16 will be present for any sample unless there is something wrong with the set-up.

Troubleshooting

If the beam cannot be found or has a low beam current:

- The cesium boiler can be "pushed"; a higher Cs boiler temperature results in higher Cs vapor pressure and higher Cs current.

Return to Lab Manuals